Turnkey PCB assembly is a service where the provider manages the full printed circuit board production process. From sourcing components to fabrication, assembly, and testing — every step is handled under one roof.

This model is ideal for businesses that want to reduce overheads, shorten time-to-market, and improve product quality. It simplifies supply chain logistics by offering a single point of contact. The result is a smooth, faster production cycle without the need to manage multiple suppliers or purchase components separately.

Unlike traditional manufacturing, PCB turnkey solutions offer complete project ownership from start to finish. Whether you're prototyping or producing high volumes, turnkey services ensure quality and cost-efficiency.

At Statron, we provide end-to-end turnkey PCB assembly services. Our capabilities cover every step of the electronic manufacturing process. Here’s what we offer:

We partner with verified global suppliers to source high-quality parts. This ensures availability, traceability, and compliance with industry standards.

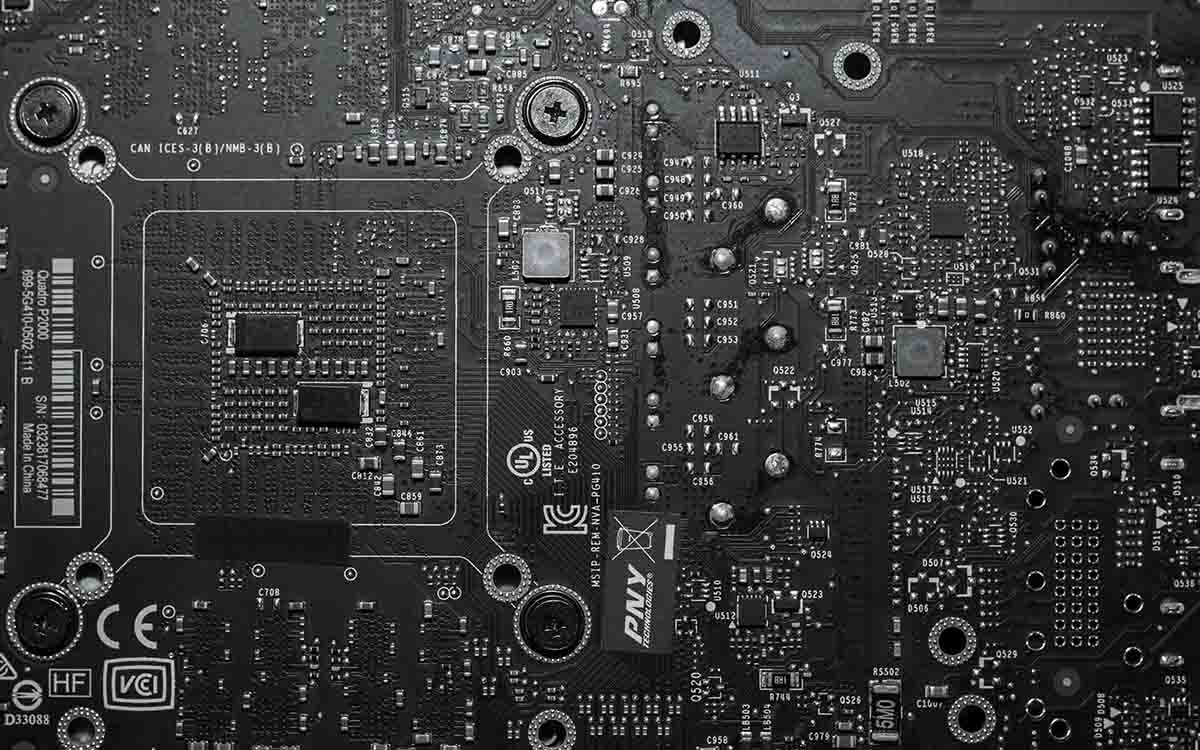

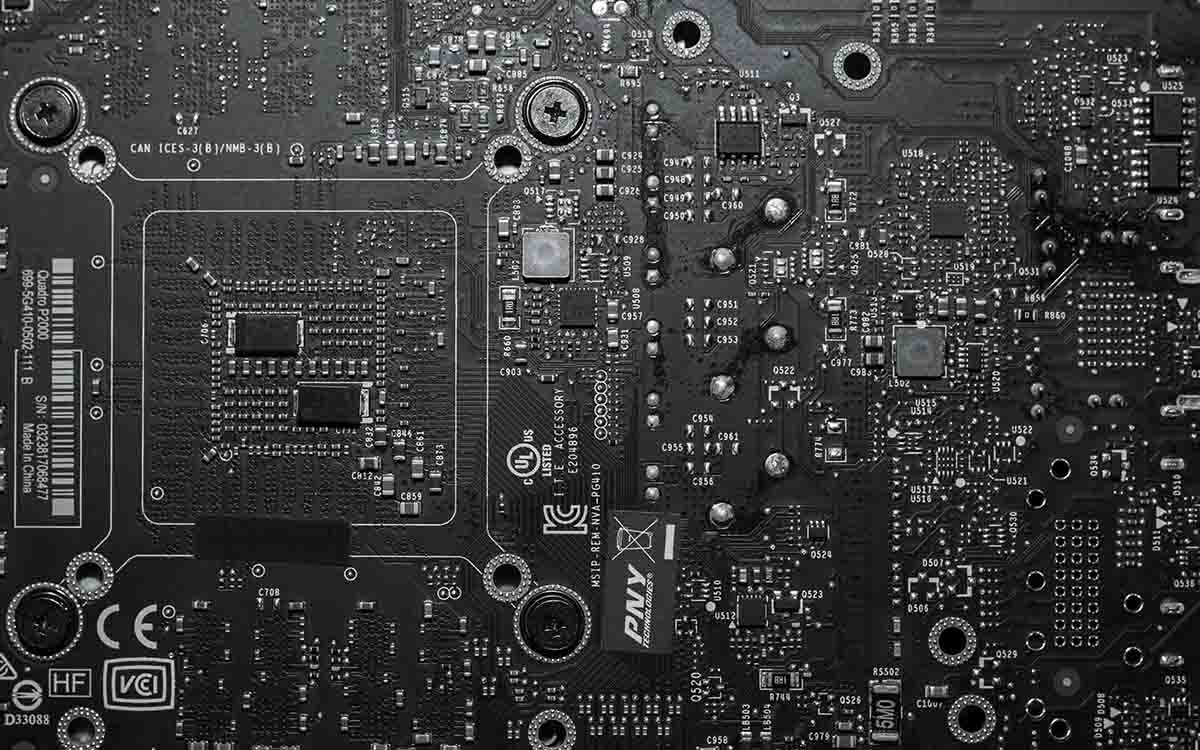

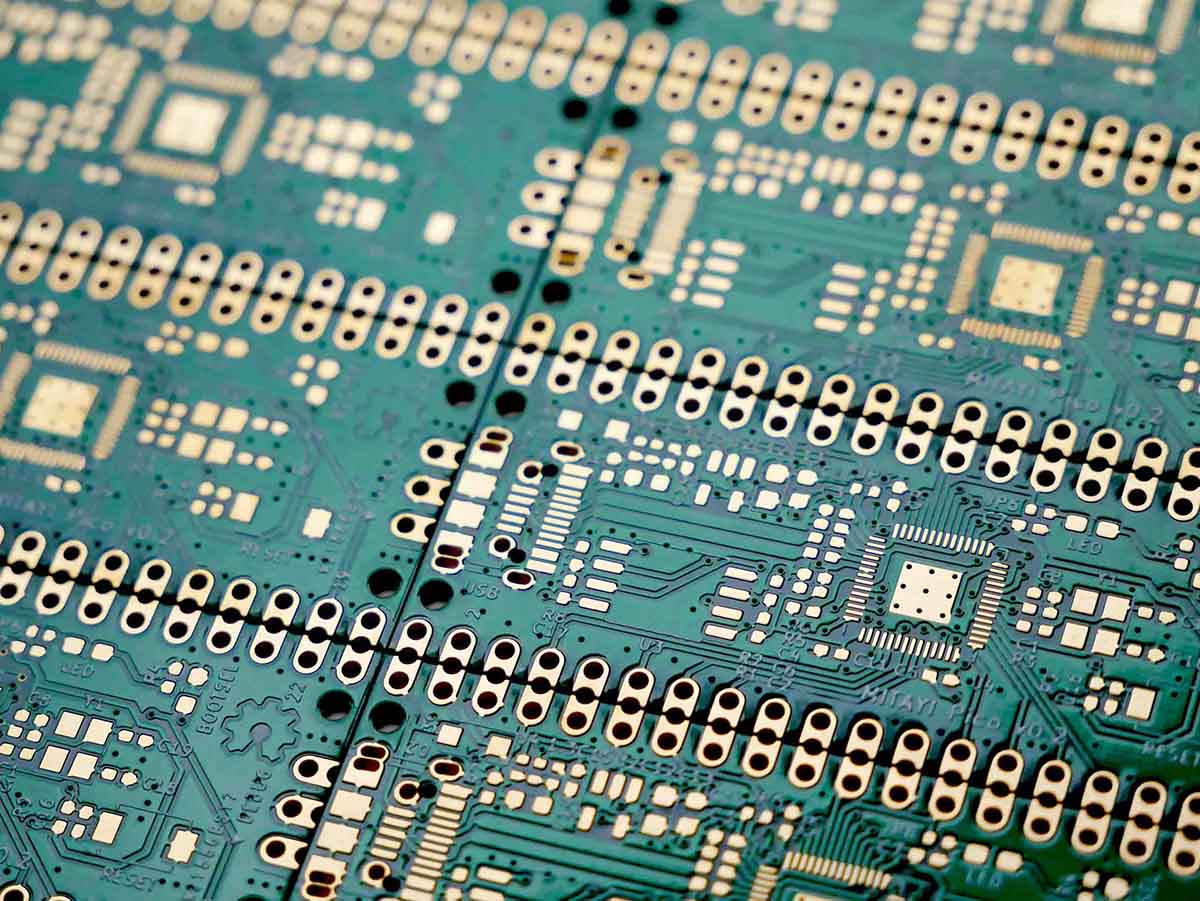

Our fabrication process delivers boards with tight tolerances, excellent layer adhesion, and consistent performance. We handle single, double, and multi-layer PCBs.

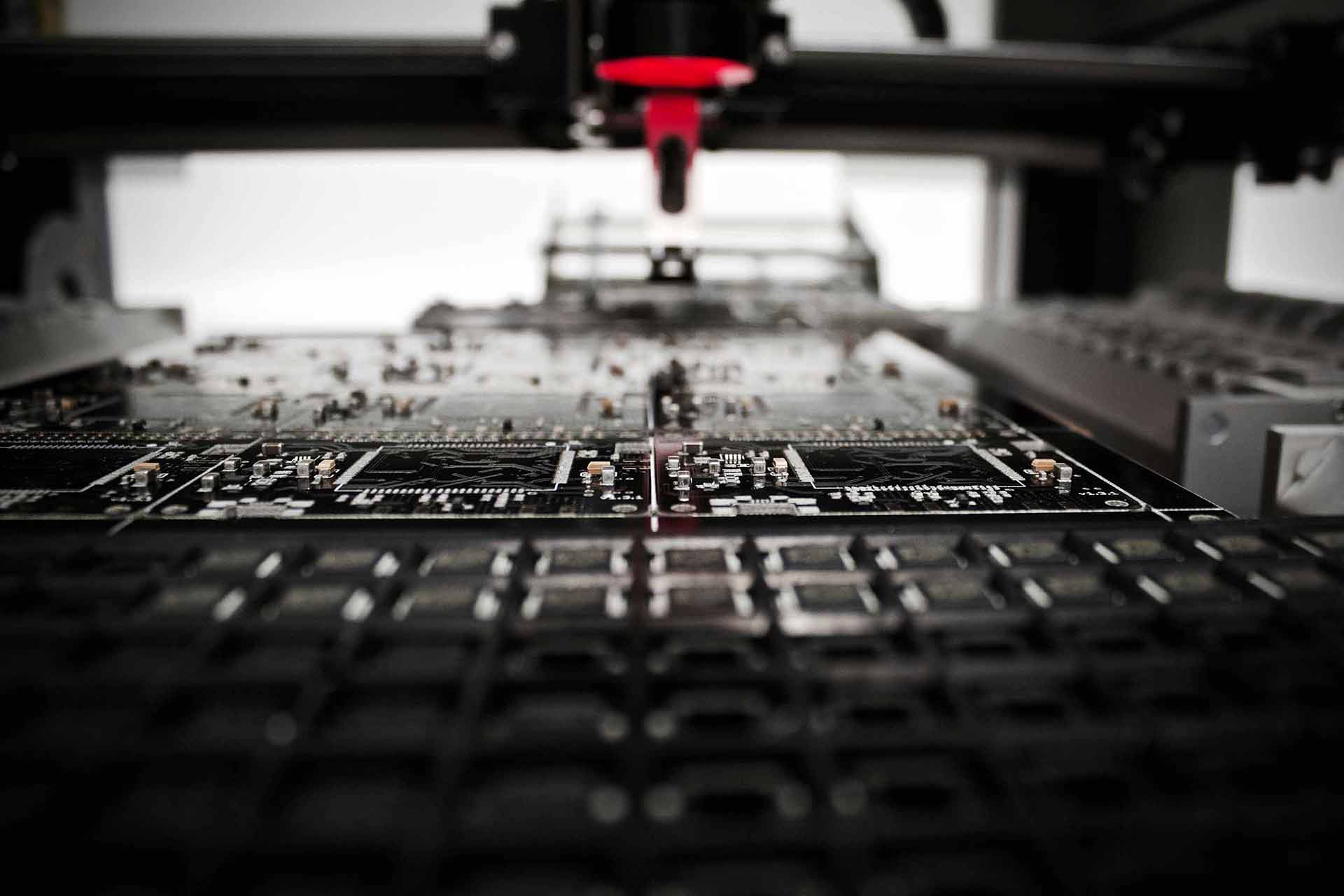

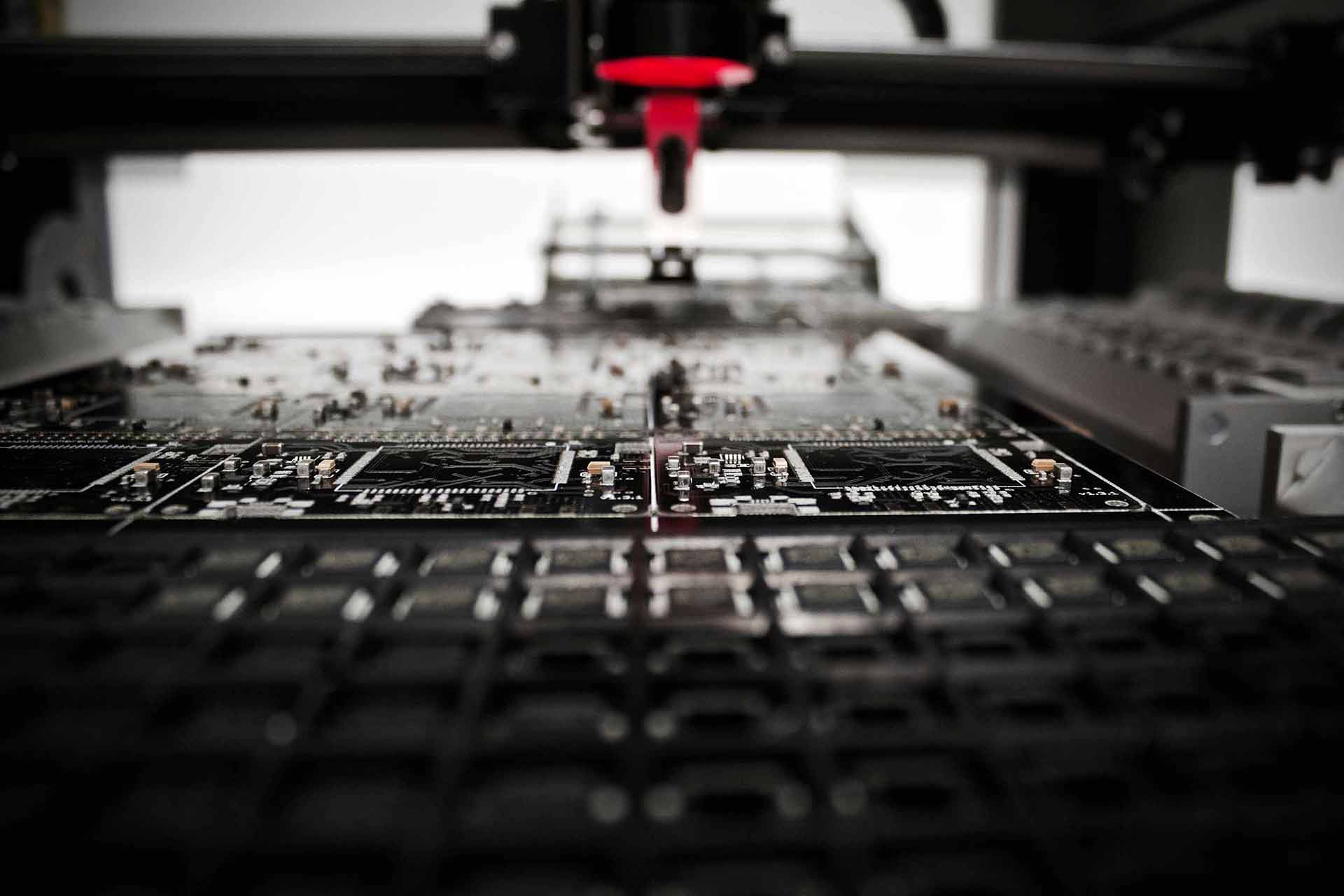

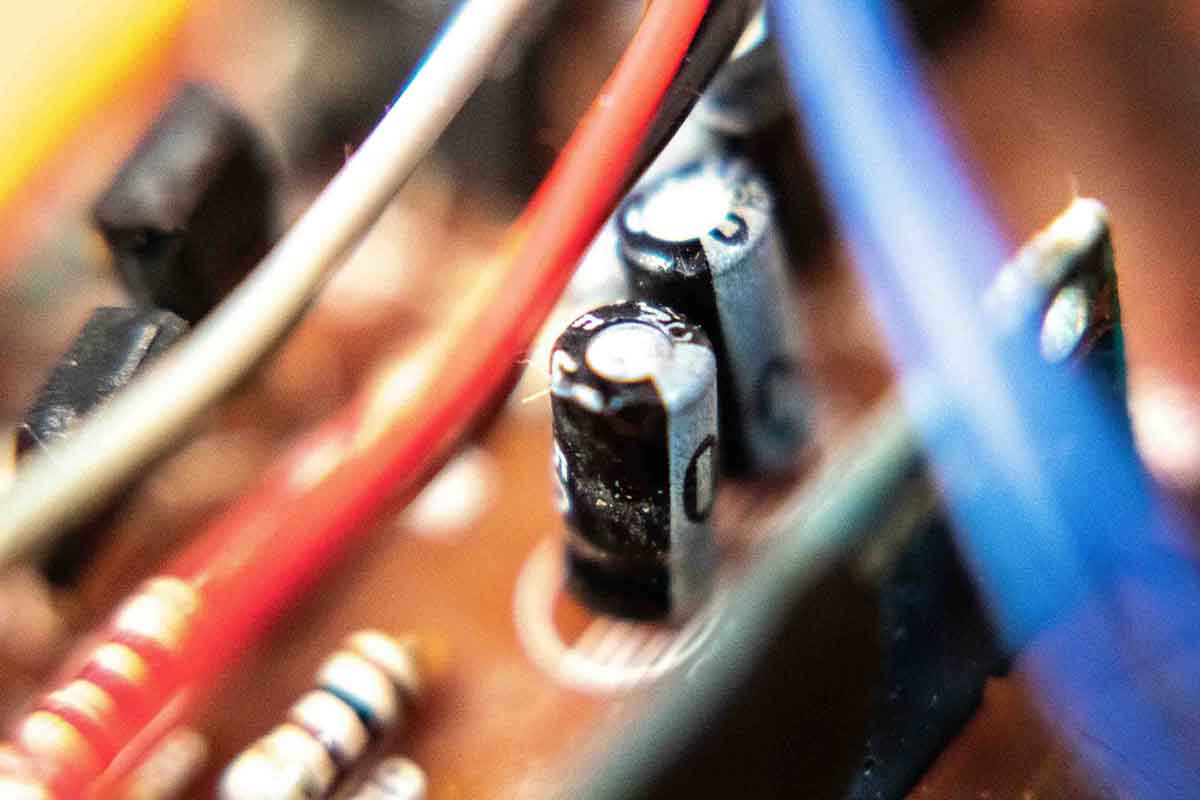

We use automated pick-and-place machines and skilled operators for surface mount and through-hole technology assembly. High-speed lines ensure precision and volume scalability.

Every board goes through rigorous electrical and functional testing. We offer in-circuit testing (ICT), automated optical inspection (AOI), and X-ray analysis for fault detection.

Beyond PCB assembly, we offer full turnkey PCB electronics integration. This includes cable harnessing, enclosures, and software loading for complete system readiness.

From small-batch prototyping to large-scale manufacturing, our flexible setup supports all stages of your product lifecycle.

We understand your business needs fast, reliable, and cost-effective PCB assembly. Here’s what sets Statron apart:

We manage everything — sourcing, assembly, testing, and delivery — so you deal with just one vendor throughout your project.

Our facility follows IPC-A-610 standards and ISO-certified practices to ensure consistent, defect-free production.

We minimise lead times through streamlined processes and smart scheduling, helping you launch your product faster.

Our team provides expert guidance from concept to completion, with fast responses and transparent communication.

We optimise procurement and reduce waste, ensuring our PCB turnkey services are competitively priced.

Whether you're building 10 units or 10,000, our infrastructure supports both prototype and high-volume production with the same commitment to quality..

We provide turnkey PCB electronics for a wide range of industries. Our adaptable services and technical skills allow us to deliver precise and reliable solutions across:

We produce high-reliability PCBs for patient monitors, diagnostic tools, and handheld medical equipment.

We support manufacturing systems, motor controllers, and PLC-based automation with rugged PCB designs.

Our solutions power networking hardware, signal processors, and communication modules.

We assist in the design and assembly of wearables, audio devices, and smart home systems.

We meet the stringent standards for mission-critical PCBs used in aerospace and defence applications.

From infotainment systems to EV chargers, our services match the automotive industry's demand for quality and performance.

Everything is handled for you — from procurement to final assembly.

Use streamlined processes to save you time and money.

Get customised solutions to meet specific project needs — from flex-rigid to 40-layer boards.

Use rigorous quality control measures for top-notch PCB performance.

Use flexible solutions that easily scale — accommodating both low volume and mass production requirements.

Get expert consultation on material selection and technologies to meet your project demands.

Our turnkey PCB assembly process follows a 6-step streamlined flow that ensures speed, accuracy, and complete control:

We analyse your design files (BOM, Gerber, pick-and-place) and identify cost, sourcing, and technical parameters.

We source all components using our global supplier network, ensuring availability, authenticity, and price optimisation.

We manufacture PCBs based on your specifications, maintaining layer consistency, trace width, and surface finish.

Our SMT and THT lines mount components with exact alignment. Skilled technicians ensure manual placements are accurate.

Each board is inspected using AOI and X-ray systems, followed by functional testing to guarantee performance.

Assembled PCBs are cleaned, labelled, and packaged securely. We manage logistics to ensure safe and on-time delivery.

We are dedicated to staying at the forefront of technological advancements.

Our commitment to continuous improvement means you receive innovative and high-quality solutions for your PCB assembly needs.

Our team is always here to help.

From the initial consultation to post-delivery support, we provide responsive and reliable service to ensure your complete satisfaction.

Ready to stay ahead with our top-notch PCB services? Let us share with you how it’s done.