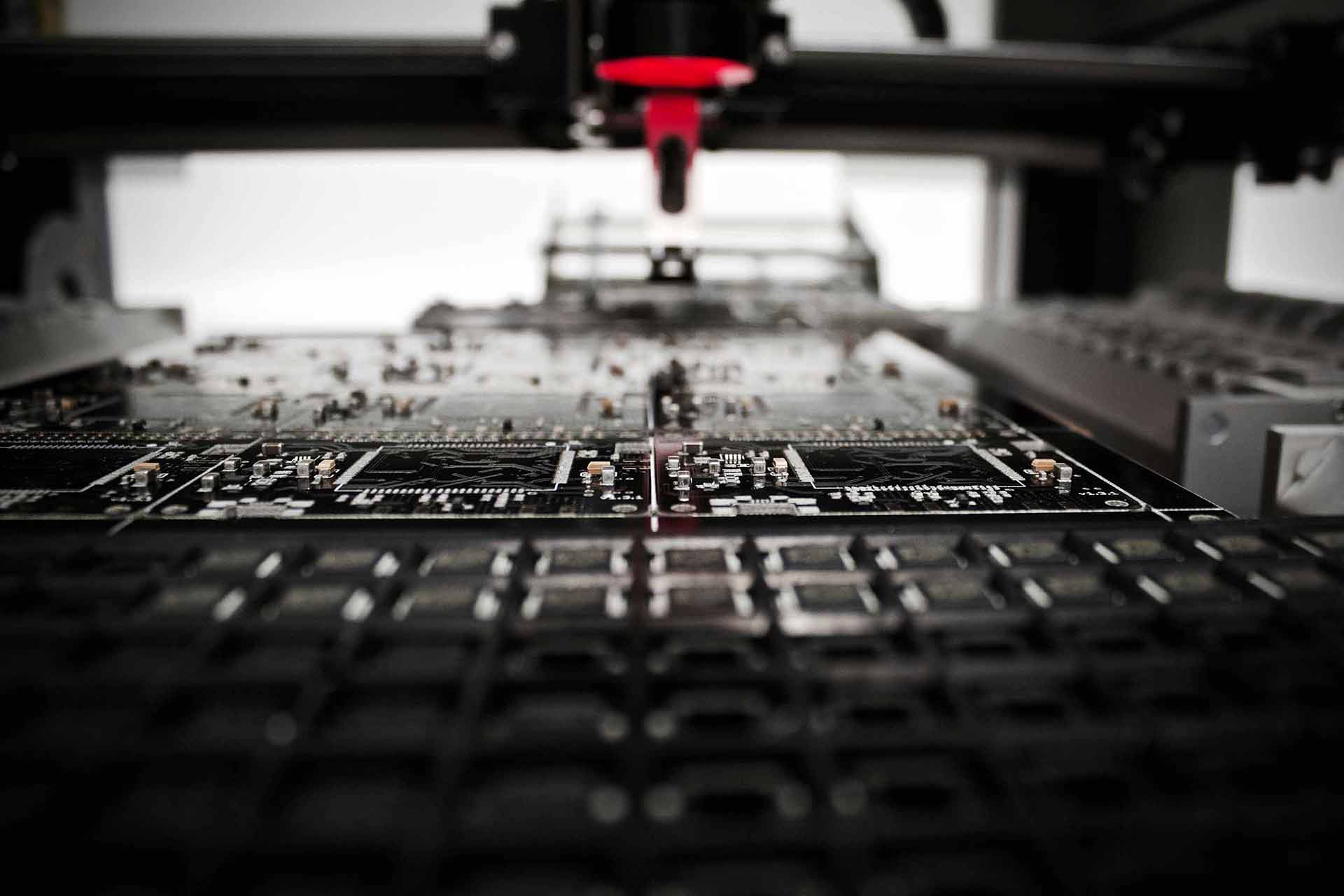

We help businesses manage their PCB design services needs through a skilled and trusted partner. Whether you're starting a new product or refining an existing one, our partner’s engineering team supports every step of your design process.

With strong experience in embedded systems and electronics, they work closely with you to turn early-stage ideas into tested and production-ready PCB layouts. The goal is simple: help you build boards that perform well, scale smoothly, and meet industry standards.

Our engineering partner has worked across different industries, offering a circuit board design service for products that must be fast, stable, and reliable. They manage everything from early drafts to production files, so you can focus on other parts of your product.

Boards are designed for electrical strength, thermal balance, and mechanical fit. From small boards to complex multi-layer layouts, the partner team ensures that your design is ready for real-world use.

Our partnered team supports the full PCB design services process. From creating basic schematics to building complex layouts, they offer reliable and practical solutions to help you move from idea to final design.

The team helps you create clear and accurate electronic schematics. They can also improve your existing circuit by checking for errors and making sure it meets the electrical needs of your product.

Layouts are made using trusted tools like Altium or KiCad. The team manages track routing, layer setup, and spacing to make sure your board works well and can be made easily.

The design is checked to make sure it’s easy to build. Good placement and sizing of parts help reduce cost, speed up production, and lower the risk of errors during assembly.

Each design is tested for stable signals. This helps avoid noise or errors, making sure the board works well for both fast digital signals and regular analogue connections.

The layout includes test points that help during checks and repairs. This makes quality checks easier and saves time during product testing before production.

The team helps choose parts that are easy to find and cost-effective. This avoids delays during manufacturing and keeps the build within your planned budget.

Designs are planned to fit well inside your product casing. The team checks space, connector positions, and heat flow to make sure everything works without problems.

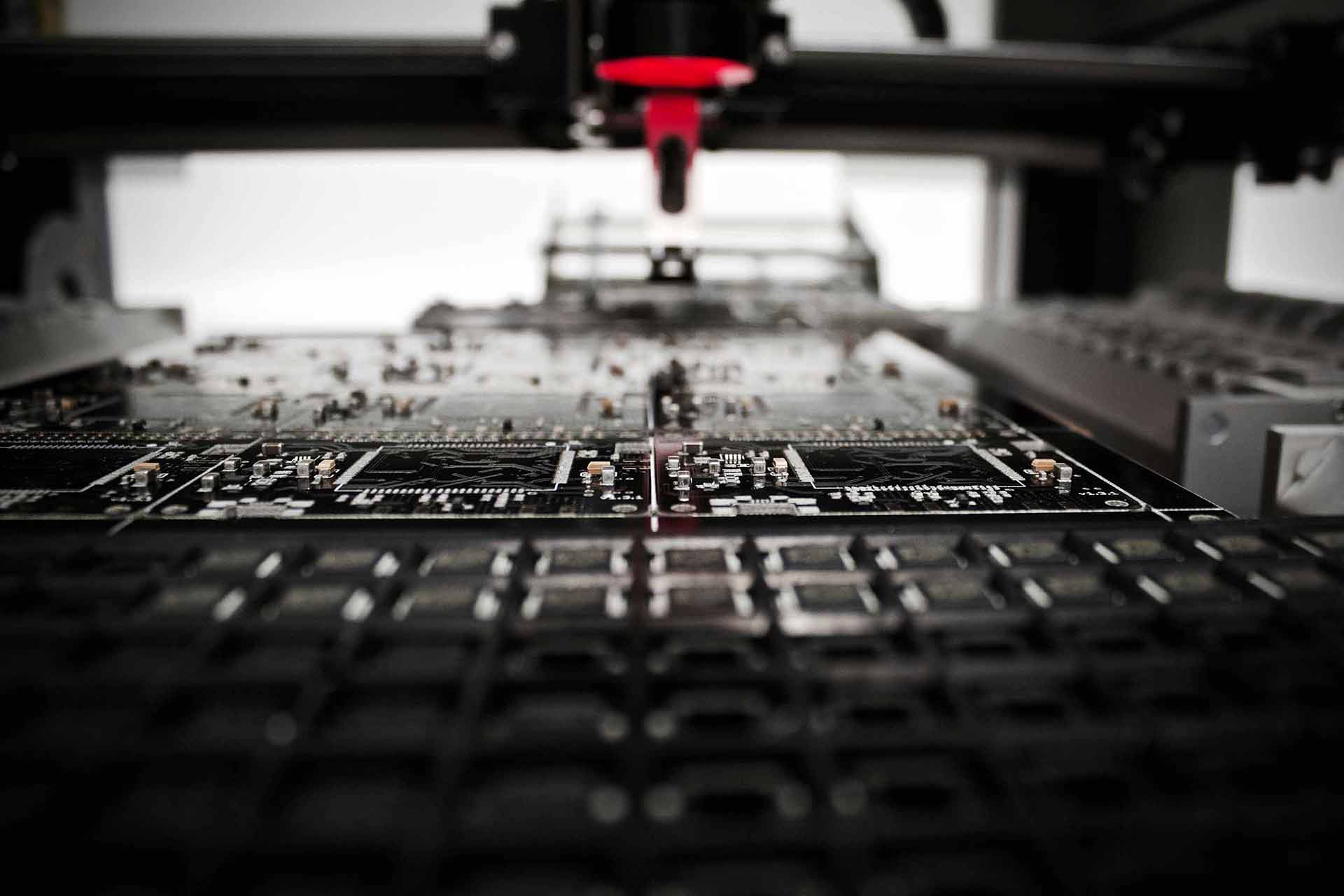

The design partner follows a clear and structured process to deliver high-quality results with transparent communication throughout.

Project size, power needs, and functionality are defined at this early stage. This sets the direction for layout, performance, and key design targets.

Schematics are created or reviewed using proven electrical design practices and sound rules to ensure a stable foundation.

Boards are laid out with careful attention to signal integrity, thermal management, and manufacturability. Every trace is placed with intent.

Designs undergo thorough rule checks and DFM reviews to catch and correct errors, ensuring fabrication readiness.

Final manufacturing files are prepared, including Gerber data, drill files, and a complete, clean bill of materials.

Designs are shared for review, and any requested changes are handled before locking the final files.

once approved, final files are handed off, or fabrication can begin through a trusted manufacturing partner.

Working with our partner brings knowledge, speed, and strong project handling. You get access to skilled design support without the need to manage each task yourself.

The partner team has years of real-world experience. They know what works and how to avoid problems during design and build.

Designs are completed on time with clear steps and updates. Speed does not come at the cost of quality.

Every board is designed to match your product needs. Layouts follow your space, power, and function limits.

Designs aim to reduce part costs and make assembly easier. This helps you stay within your budget.

The partner covers the full layout process from start to finish. This removes stress from your workflow.

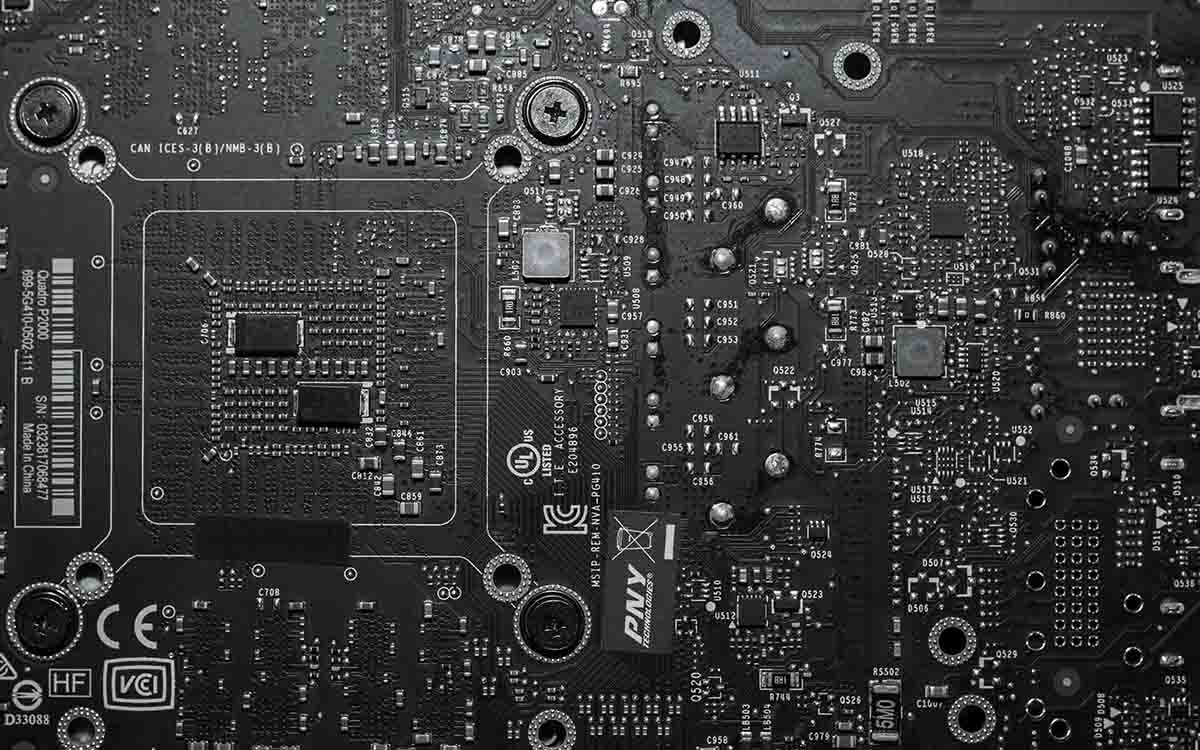

We work with a trusted PCB design partner who supports a wide range of industries. Their expertise helps create reliable and purpose-built circuit boards for many use cases, including:

Boards are designed to support sensors, controllers, and machines used in factory and process automation. These layouts help improve durability, safety, and steady operation in industrial settings.

From smart gadgets to home devices, the designs focus on saving space and cost. Boards are built to support compact layouts while maintaining clear signals and smooth performance.

Layouts are created for health monitors, diagnostic tools, and similar products. They follow key safety rules and ensure reliable signal flow for accurate results in healthcare use.

Designs are planned for small, power-saving boards. These are used in wireless setups, edge computing, and connected products where size and energy use are important.

Boards are built to handle shocks, heat, and motion. These support use in EVs, safety systems, and dashboards, where stable function is a must.

PCB layouts help run systems like solar inverters, battery storage, and control units in smart grids. Designs aim for long life and steady use in energy environments.

Designs work in systems for access control, motion sensors, and cameras. Boards are planned to give stable performance across both home and business security setups.